Heating mechanochemical reactions using near-infrared irradiation – it’s possible!

Researchers from the Green Chemistry and Enabling Technologies team at the Institut des Biomolécules Max Mousseron (IBMM) and the Macromolecular Chemistry and Material department at the Charles Gerhardt Institute (ICGM) (CNRS/Université de Montpellier/ENSCM) have developed an innovative approach to heating mechanochemical reactions during solvent-free ball-milling, in order to achieve reactions with high activation energy.

Mechanochemistry, and more specifically ball-milling, has seen a resurgence of interest in recent years, as this technology enables working with solid reagents in the absence of solvents. In addition to avoiding the use of often toxic and polluting solvents, the benefits of this approach range from improved reaction times, efficiency and yields to easier purification and isolation of products. However, chemists are at a loss when it comes to heating the reaction medium for reactions with high activation energy. Various approaches currently exist, but the most promising are limited to the use of conductive materials (stainless steel) for the grinding jar or ball.

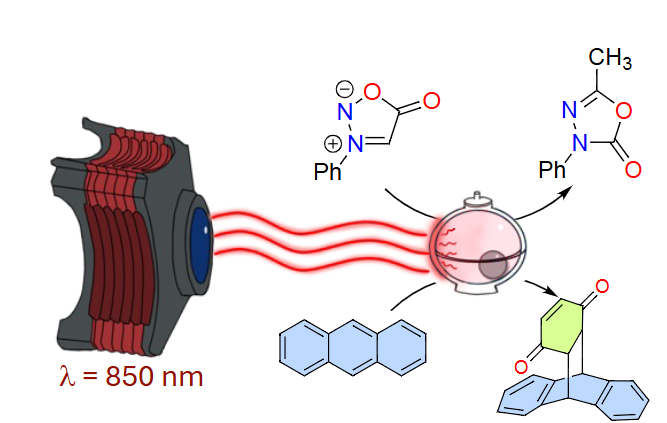

As part of the ANR (Agence Nationale de la Recherche) FunctioMill project, IBMM’s Green Chemistry and Enabling Technologies team (Frédéric Lamaty and Xavier Bantreil) and researchers from the ICGM’s Macromolecular Chemistry and Materials department (Julien Pinaud) are proposing a new approach to heating in mechanochemistry that is inexpensive, practical, safe for the user, adaptable to different types of vibratory ball-mills and does not require the use of conductive materials. The idea is to introduce an organic pigment, IR-813 p-toluenesulfonate, with photothermal properties, into the reactor composition. Under near-infrared irradiation, this molecule absorbs photons and releases most of the energy in the form of heat.

Original reactors made from epoxy resin, a material first used in mechanochemistry, have been developed. By screening different formulations, a resin capable of producing grinding jars that are both mechanically and chemically resistant was selected. With the incorporation of 1% in mass of IR-813 pigment during resin cross-linking, reactors capable of reaching an internal temperature of 120°C under irradiation at 850 nm were fabricated.

The viability and usefulness of the heating reactors, placed during the milling phase under a near-infrared irradiation lamp, were then demonstrated in organic synthesis in Diels-Alder reactions with high activation energy, as well as in the rearrangement of a sydnone into an oxadiazolinone, a reaction which requires additional energy input during milling. In the absence of irradiation, little or no expected product is obtained during milling, whereas the presence of near infrared irradiation gives excellent yields.

The use of epoxy resin as a material for the future of ball-milling and the manufacturing of the first generation of heating reactors under near infrared irradiation suggests equally interesting future applications, whether in the design of new reactor types or the improvement of their properties, and the modification of their composition for dedicated tasks.

Reference : Joao Tanepau, Hafsa Bonnaanaa, Angèle Macé, Arthur Guérin, Philibert Lenormand, Frédéric Lamaty, Julien Pinaud, Xavier Bantreil, Angew. Chem. Int. Ed., 2024, e202419354. Lien : https://onlinelibrary.wiley.com/doi/10.1002/anie.202419354