https://ibmm.umontpellier.fr/wp-content/uploads/2025/06/Morgan.jpg

226

400

Caroline Clavel

https://ibmm2.umontpellier.fr/wp-content/uploads/logo_ibmm_hd.jpg

Caroline Clavel2025-06-19 16:40:542025-06-19 16:51:18Morgan Pellerano présente son métier sur le site de l’UM

https://ibmm.umontpellier.fr/wp-content/uploads/2025/06/Morgan.jpg

226

400

Caroline Clavel

https://ibmm2.umontpellier.fr/wp-content/uploads/logo_ibmm_hd.jpg

Caroline Clavel2025-06-19 16:40:542025-06-19 16:51:18Morgan Pellerano présente son métier sur le site de l’UM- En savoir +

L’Institut des Biomolécules Max Mousseron est une Unité Mixte de Recherche (UMR 5247) UM, CNRS, ENSCM qui développe des recherches à l’interface de la chimie, de la biologie et de la santé intégrant les enjeux du développement durable : nourrir, soigner, protéger.

Actualités

https://ibmm.umontpellier.fr/wp-content/uploads/2025/06/Morgan.jpg

226

400

Caroline Clavel

https://ibmm2.umontpellier.fr/wp-content/uploads/logo_ibmm_hd.jpg

Caroline Clavel2025-06-19 16:40:542025-06-19 16:51:18Morgan Pellerano présente son métier sur le site de l’UM

https://ibmm.umontpellier.fr/wp-content/uploads/2025/06/Morgan.jpg

226

400

Caroline Clavel

https://ibmm2.umontpellier.fr/wp-content/uploads/logo_ibmm_hd.jpg

Caroline Clavel2025-06-19 16:40:542025-06-19 16:51:18Morgan Pellerano présente son métier sur le site de l’UM

Grand succès pour le congrès Mech’cheM !

Grand succès pour le congrès Mech'cheM qui s'est déroulé…

16 équipes de recherche

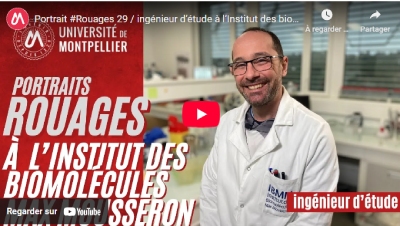

Synthèse stéréosélective & acides aminés modifiés

10 janvier 2024/par Stephanie HERNANDEZ

Sciences analytiques des biomolécules

10 janvier 2024/par Stephanie HERNANDEZ

Glyco et Nanovecteurs pour le ciblage Thérapeutique

10 janvier 2024/par Stephanie HERNANDEZ

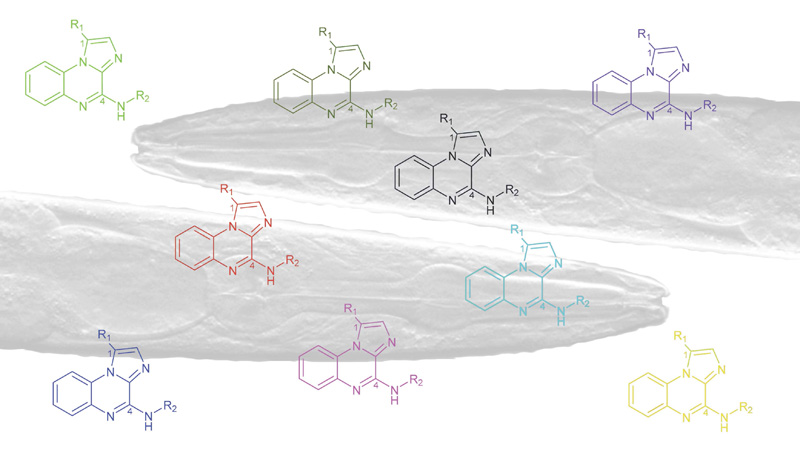

Oncopharmacochimie & Pharmacotoxicologie Cutanée

10 janvier 2024/par Stephanie HERNANDEZ

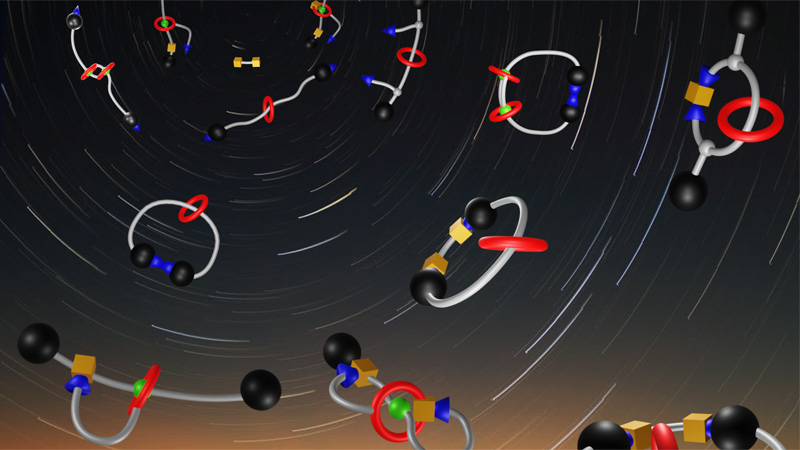

Supramolecular MAchines and ARchitecture Team

10 janvier 2024/par Stephanie HERNANDEZ

ChemBioNAC

10 janvier 2024/par Stephanie HERNANDEZ

Dynamique des Systèmes Biomoléculaires Complexes

10 janvier 2024/par Stephanie HERNANDEZ

Acides aminés, hétérocycles, peptides & protéines

10 janvier 2024/par Stephanie HERNANDEZ

Glycochimie & reconnaissance moléculaire

10 janvier 2024/par Stephanie HERNANDEZ

Polymères pour la Santé et Biomatériaux

10 janvier 2024/par Stephanie HERNANDEZ

Chimie Verte et Technologies Innovantes

10 janvier 2024/par Stephanie HERNANDEZ

Pharmacologie Cellulaire

10 janvier 2024/par Stephanie HERNANDEZ

Pharmacochimie, transmission synaptique & neuroprotection

10 janvier 2024/par Stephanie HERNANDEZ

Oncothérapie et oncopharmacologie

10 janvier 2024/par Stephanie HERNANDEZ

Synthèse de Lipides Bioactifs

10 janvier 2024/par Stephanie HERNANDEZ

Offre de thèse : PHOTOCLICK: Development of biorthogonal photo-crosslinking reactions for 3D printing micro-structured biomaterials

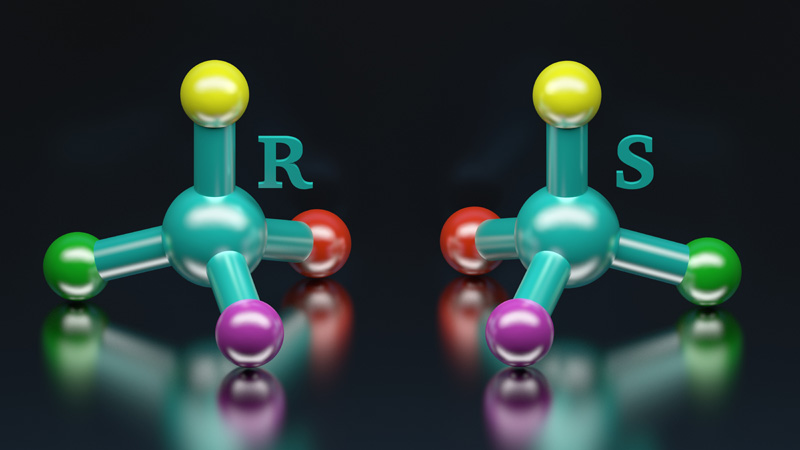

Contract: 3 years starting from October 2025 Application deadline: 04/07/2025 Location: Institute of Biomolecules Max Mousseron (IBMM), Montpellier, France and Institute for Molecular Systems Engineering and Advanced Materials (IMSEAM), Heidelberg, Germany The project This thesis project is located at the interface of click chemistry, photochemistry, materials, 3D printing and biology. The goal is to […]

Offre de thèse : Advanced 4D biomaterials for mucosa and sub-mucosa treatment in patients affected by intestinal diseases (Daedalus)

ADVANCED 4D BIOMATERIALS FOR MUCOSA AND SUB-MUCOSA TREATMENT IN PATIENTS AFFECTED BY INTESTINAL DISEASES (Daedalus) financed by the EU program HORIZON EUROPE 4D biomaterials enable new surgical treatments by autonomously acting in response to environmental stimuli, thus overcoming the limitations of standard medical strategies. DAEDALUS is a European project that gathers 13 partners and […]